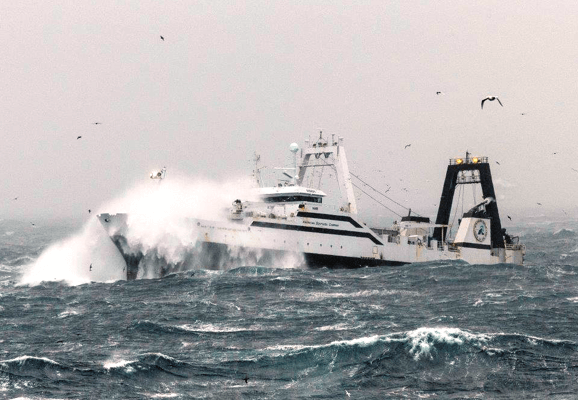

THE WORLD’S MOST ADVANCED FLEET

Our fleet of seven Det Norske Veritas (DNV) fishing vessels uses leading-edge technology to fish and sustainably manage the fisheries of the North Pacific Ocean and the Bering Sea. Regular equipment upgrades and pioneering fishing practices help improve efficiencies and minimize environmental impact.

Our vessels process, package, and quickly freeze every product we make while still at sea ensuring quality that surpasses that of shore-based processors.

JOIN OUR CREW

Think you’ve got what it takes to join us at sea? View our job openings, and then let’s talk. Reach out anytime.

VESSEL TECHNOLOGY

HIGH EFFICIENCY, LOW ENVIRONMENTAL IMPACT

State-of-the-art equipment and pioneering technologies aboard our vessels allow American Seafoods to harvest, process, and freeze our catch while still at sea to lock in freshness, taste, and nutrition. From bow to stern, our gear is masterfully engineered to fully utilize the fishery resources of the Bering Sea and the North Pacific Ocean. And regular upgrades not only help improve processing efficiencies but also help minimize environmental impact.

PASSION FOR THE WORK

It takes something extra to work long hours in distant waters. Our people bring a passion for the sea, respect for the fishery, and pride for doing an important job—and doing it well.

EXPERTISE AT SEA

As one of the world’s largest at-sea processors, American Seafoods attracts highly skilled seagoing men and women from more than 90 countries. The average experience is about 15 years.

SHIPWIDE EXPERIENCE

1. WHEELHOUSE

Our deeply experienced wheelhouse staff includes the captain and the first mate, who are in charge of operations on the entire vessel.

2. DECK

Deckhands get plenty of fresh air while dealing with the fishing gear used to deploy and retrieve nets.

3. GALLEY

The galley staff cooks meals for the crew, does laundry, and cleans the ship.

4. FACTORY

As the largest crew on the boat, the factory staff works below deck in the fish processing and packaging areas.

5. ENGINES

Engine crew members keep motors and onboard power equipment running smoothly throughout the mission.